Looking for laser alignment The machines and equipment that are mostly used in big industries need to be improved that will enhance their overall performance. To maintain the alignment of these machines and equipment, the latest method that is now widely used is known as laser alignment. If a machine is not aligned in a perfect way, it might face minor issues to major repairing issues.

Laser Alignment:

The proper alignment of a machine is important because if the alignment of a machine will not be perfect, it will not work in an appropriate way and the overall performance will also be affected. To avoid any kind of inconvenience and malfunctioning of the machinery, the owner of the business will have to hire professional services in time to make their machinery aligned.

Why do you need to get the suggestion of an expert about using laser alignment?

If the owner of a business will not pay attention on the misalignment of a machine then he will have to pay high costs on fixing machines. To make the machinery of your workplace performing in the best way for the long run, the owner must consider using the laser alignment tool for a shaft.

It is not easy for some workers to use this kind of tool if they will not be an expert. It will be better for the owner to consider hiring the professional services of a company that has got great experience of using this particular tool to align the machinery. These professionals will align the shaft along with providing professional suggestions to maintain the performance of the machinery for the future.

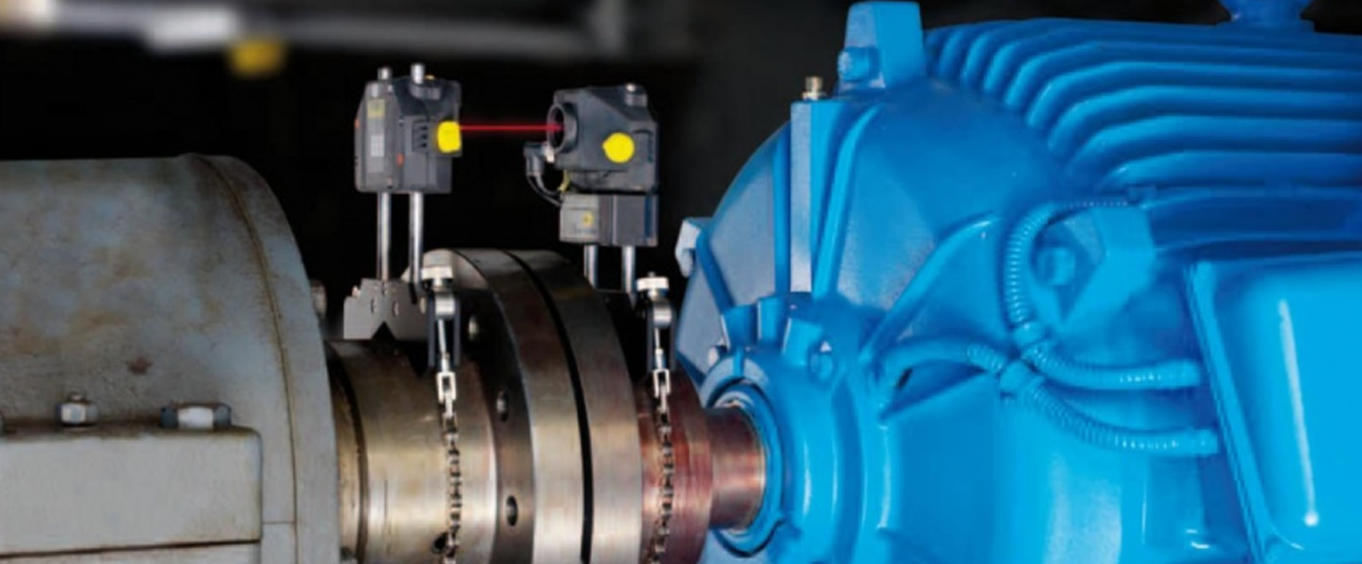

One of the significant benefits is using the laser alignment tool for the shaft will analyze the misalignment and will set the accuracy and alignment of the machine by using the laser. Another benefit of using this tool is that the misalignment of the shaft within the machine will also be fixed.

Use of laser alignment in the modern machinery world:

If a machine becomes misaligned, it will face great wear and tear and the worker working on it will have to consume a lot of energy on fixing it. If a machine will be working hard then it will consume increased energy. In this situation, you will have to pay for a long run against power consumption.

Therefore, using an easy laser alignment will reduce unnecessary wear and tear on bearings and seals, which will save you from spending a lot of money. In the event you have a machine that requires you to change the bearings and seals every couple of months, then it’s time to consider the alignment of the machinery. For more information visit our Website.