Looking for machine alignment laser Modern manufacturing tools and machines allow manufacturers to produce large amounts of merchandise in less time but at a fast speed. It not only produces things in bulk which are readily available in the market, but it also helps in lowering the production cost.

Machine Alignment Laser:

Advanced manufacturing tools and machines provide technological and medical achievements. It has made our society modern and advanced. But all these things will run smoothly if the manufacturing works properly and it could be possible when all the machines are set to accurate measurements. Therefore, a machine alignment laser is used that helps in manufacturing to work properly.

If the machines are not aligned properly and to the exact measurements, then a lot of problems can occur. These problems could end up causing maintenance difficulties, poor product quality, and increased overhead. This is the reason why laser alignment is preferred in all industries of manufacturing as an aligned machine and best shaft alignment promotes the consistent production of duplicate items.

How precision alignment helps:

It is one of the most important parts of all industrial applications; that’s why correct and precise measurements are needed to make the manufacturing work properly. There are various problems that occur due to the misalignment of machines. So accurate alignment is required to run the machines efficiently, and due to this, a lot of problems are fixed, such as uneven thickness, web breaks, baggy edges, and poor web tracking. And when perfect and precise alignment is required, manufacturers mostly used laser trackers to enhance the quality of products and promote efficiency.

Industrial laser alignment:

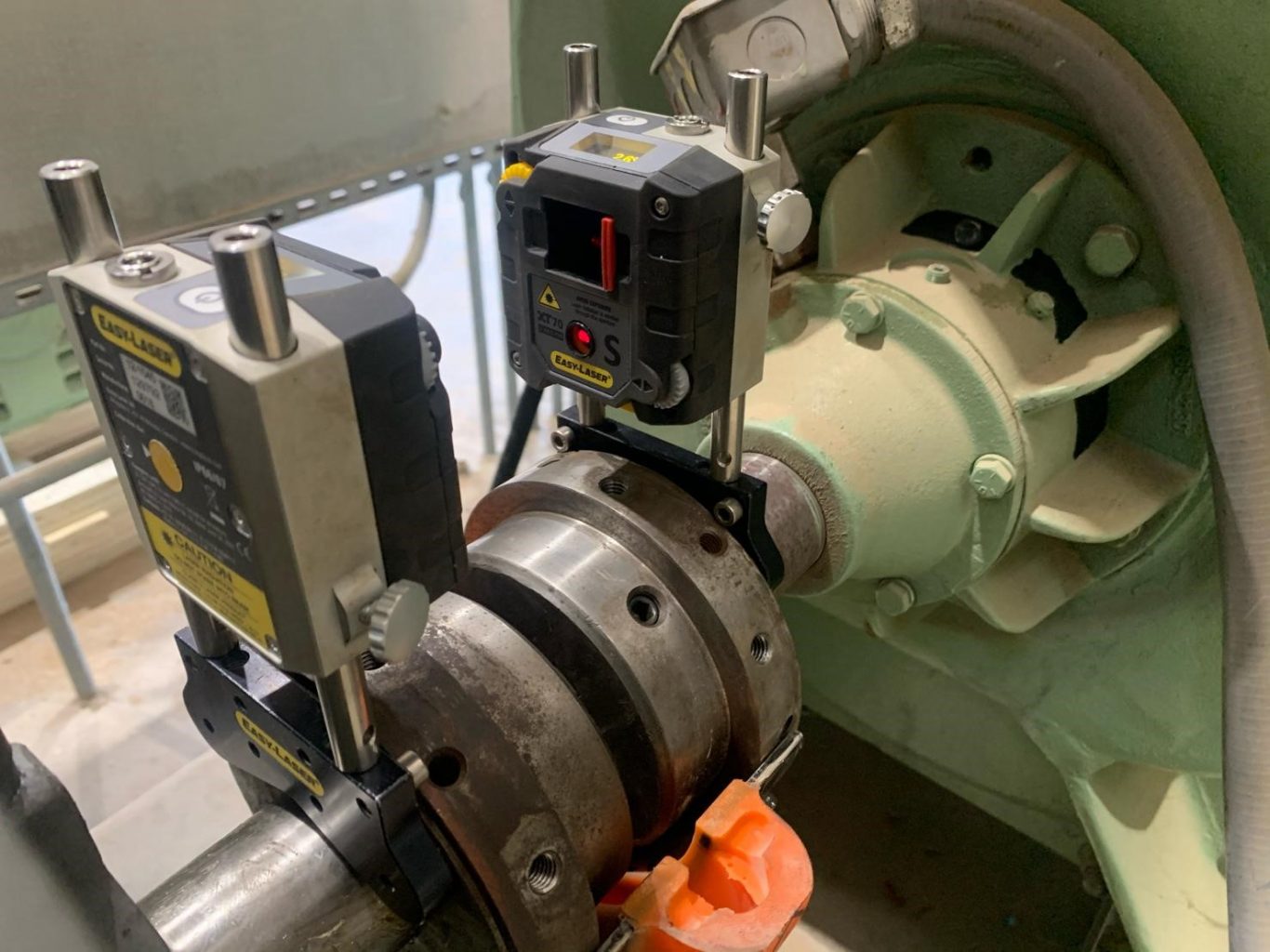

There are various alignment tools that are used for the machine alignments, such as laser shaft tools, pulley alignment tools, and laser trackers. The laser tracker is the most commonly used alignment tool, which is basically a portable device. This tool uses laser light in order to measure a spherical volume. Normally, this volume can range up to 60 meters. And depending on the versatility of the device, it allows the operator to inspect and measure objects of different sizes. Moreover, these laser tools are very efficient and reliable and are mostly used for all kinds of manufacturing industries.

Repeatable and dependable accuracy:

The best thing about a machine alignment laser tool is that it offers repeatable and dependable accuracy. Therefore, manufacturers are fully allowed to obtain numerical repeatability and, at the same time, eliminate the risk of error. For more information visit our Website.