The SWMS, or safe work method statement electrical, was initially designed for people working in the construction sector. However, other sectors and companies have begun to include it in their safety management system throughout the years.

When writing the SWMS, there are a few factors to bear in mind. First, companies or managers must do sufficient study on the kind of jobs they give to their staff. What kinds of health and safety risks are expected to result from it? What countermeasures should be implemented? Employers must next find out how to make the safe work method statement carpentry statement understandable to their staff.

The paper must be prepared in clear and straightforward English so that it may be understood by workers with low literacy levels. Employers should also speak with their workers on the kind of workplace risks they face on daily work. Once everything is in place, the Method Statement may be written.

The SWMS for electrical work is almost identical to the majority of Method Statements. A safe work method statement electrical is comprised of the items listed below.

Documentations

The first section of the document contains the job or task to be completed, the people allocated to the task, and the control measures to be implemented to prevent or reduce workplace risks. Personnel doing electrical work, for example, are at risk of electric shock and electrocution burns. The document should include the control mechanisms to be used to prevent such issues, as well as the safe work techniques and training those workers must undergo before being permitted to work.

Preparation

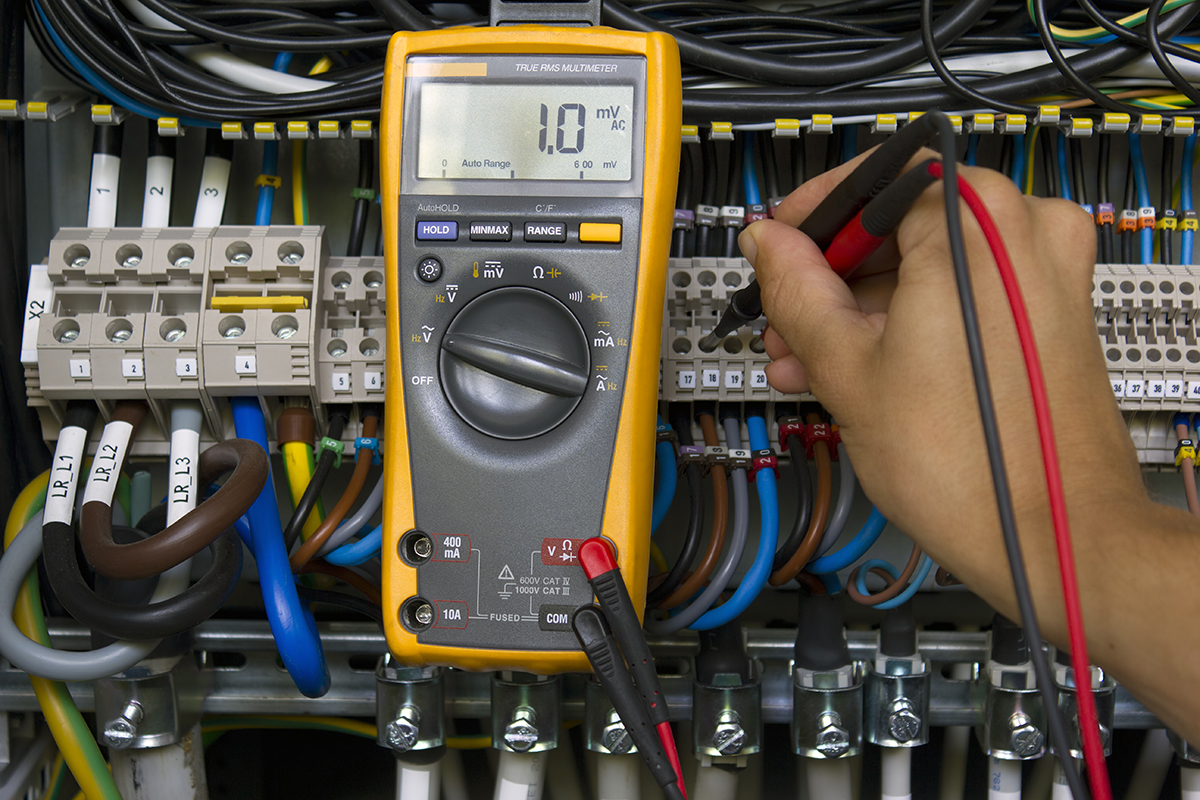

The second section of the text focuses on the site safe work method statement carpentry preparation. Before workers are permitted to carry out the duties given to them, the workplace must be inspected. The examination should establish whether or not the workplace complies with the health and safety standards required of the industry. In addition to the workplace, the equipment utilized is examined.

Inspection Timetable

The paper then specifies the inspection timetables for the specific activities involved. The third section of the paper is all about creating a system for frequent testing of equipment by an expert.

Working

This section of the safe work method statement electrical paper specifies how the equipment or machinery should be operated in accordance with the manufacturer’s instructions. It also explains what steps should be followed if the equipment utilized malfunctions or becomes damaged. Accidental countermeasures are also included here.